Our Quartz Glass Products

Specializing in bespoke quartz glass solutions, we tailor everything from tubes and plates to intricate glassware and semiconductor components to your precise specifications. Wholesale inquiries welcome.

Quartz Product

Semiconductor Quartz

Verified Quality, Trusted Expertise

Our dedication to excellence is backed by internationally recognized certifications like ISO and SGS, and further proven by our innovative patents. These credentials demonstrate our rigorous standards and commitment to delivering consistently superior quartz glass solutions you can rely on.

S9001

S14001

SGS

Patent

High-Performance Quartz Reaction Tubes

Engineered for superior chemical inertness and thermal stability in your critical applications.

High Purity Quartz Glass Test Tubes – Extreme Temperature & Chemical Resistance

High Purity Quartz Glass Test Tubes – Extreme Temperature & Chemical Resistance

Pickup currently not available

Quartz Test Tube with Ground Glass Stopper | High Temperature & Sealed

Quartz Test Tube with Ground Glass Stopper | High Temperature & Sealed

Pickup currently not available

High Purity Quartz Schlenk Tube with Stopcock | For Vacuum & Inert Gas Reactions

High Purity Quartz Schlenk Tube with Stopcock | For Vacuum & Inert Gas Reactions

Pickup currently not available

High Purity Custom Quartz Chloride Ion Reaction Tube | Fused Silica Analysis Vessel

High Purity Custom Quartz Chloride Ion Reaction Tube | Fused Silica Analysis Vessel

Pickup currently not available

Durable & Versatile Quartz Boats

Crafted for secure sample handling and stability in high-temperature applications

Custom High Purity Quartz Boat for Tube Furnaces – Single Ear & 1200°C Acid Resistant

Custom High Purity Quartz Boat for Tube Furnaces – Single Ear & 1200°C Acid Resistant

Pickup currently not available

High Purity Quartz Boat with Dual Handles for Elemental Analysis

High Purity Quartz Boat with Dual Handles for Elemental Analysis

Pickup currently not available

High Purity Quartz Boats with Anti-Slip Lids | Customizable

High Purity Quartz Boats with Anti-Slip Lids | Customizable

Pickup currently not available

High-Purity Rectangular Quartz Boats & Trays for Tube Furnaces | Custom Fused Silica Sample Holders

High-Purity Rectangular Quartz Boats & Trays for Tube Furnaces | Custom Fused Silica Sample Holders

Pickup currently not available

Precision Quartz Labware for Scientific Excellence

Superior purity and resistance for your most demanding analytical procedures

High Purity Quartz Glass Square Tanks & Containers – Custom Fabricated

High Purity Quartz Glass Square Tanks & Containers – Custom Fabricated

Pickup currently not available

High Purity Quartz Glass Crucibles – Extreme Temperature & Corrosion Resistance

High Purity Quartz Glass Crucibles – Extreme Temperature & Corrosion Resistance

Pickup currently not available

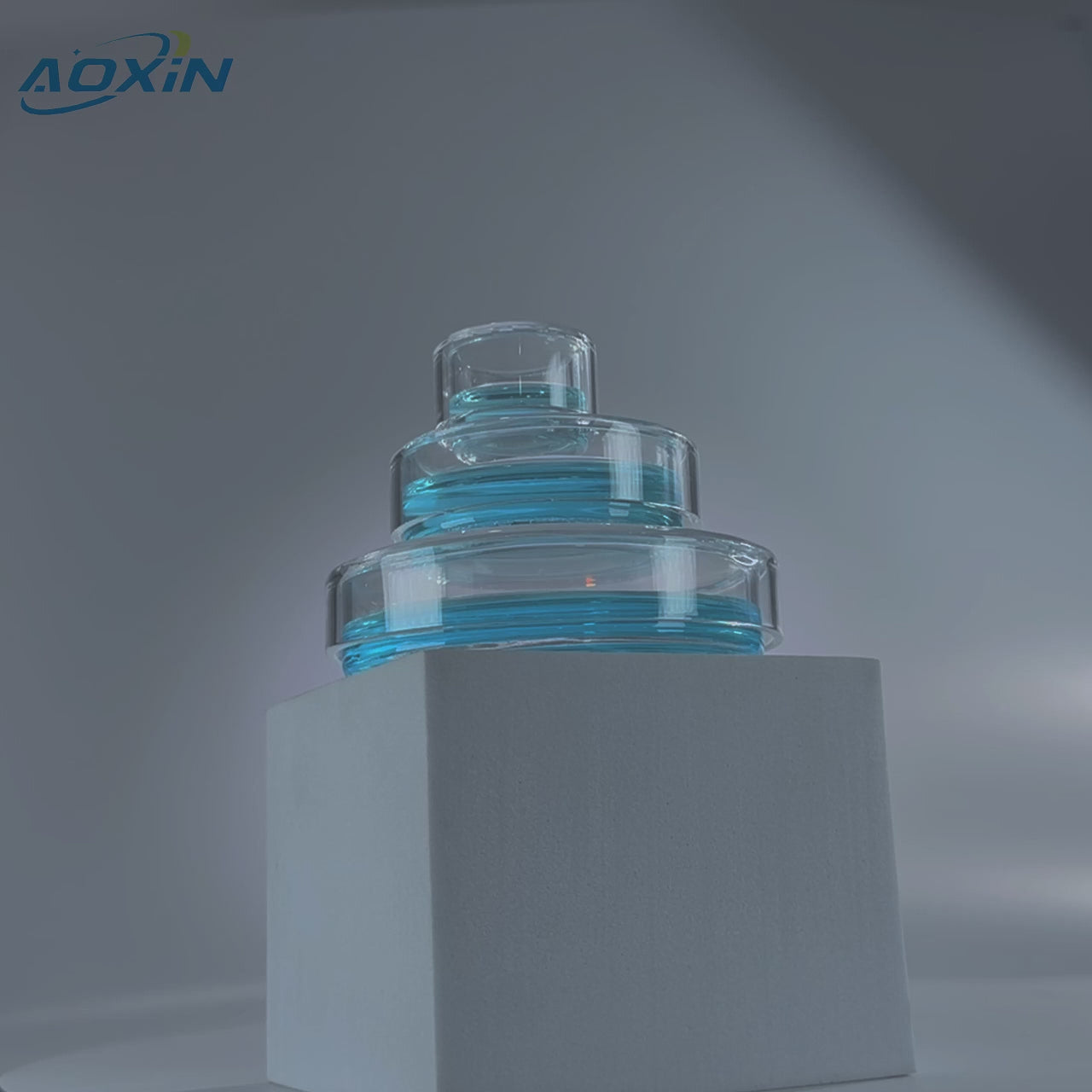

High Purity Quartz Glass Petri Dishes – UV Grade & Extreme Temp Resistance

High Purity Quartz Glass Petri Dishes – UV Grade & Extreme Temp Resistance

Pickup currently not available

High Purity Quartz Evaporating Dishes & Fused Quartz Evaporation Vessels | 1200°C Heat Resistant Labware

High Purity Quartz Evaporating Dishes & Fused Quartz Evaporation Vessels | 1200°C Heat Resistant Labware

Pickup currently not available

One-Stop Source for Custom Quartz Glass Components

Expert OEM/ODM Services

With a decade of dedicated experience, Aoxin Quartz is your specialist in manufacturing high-quality, precision quartz glass components. We empower leading instrument brands globally with expert OEM/ODM services and supply premium quartz products to renowned universities, semiconductor manufacturers, and photovoltaic innovators. Partner with us to leverage our complimentary precision design solutions and rapid prototyping services.

Proven Expertise, Lasting Partnerships

Our decade of custom quartz glass expertise forms the bedrock of lasting partnerships – 90% of our clients choose us for the long term. We deliver comprehensive processing solutions, from initial concept to finished quartz components, meticulously tailored to your unique requirements.

Rapid Response, Efficient Design

Experience unparalleled service efficiency: receive an initial response within 5 minutes, clear communication within 30 minutes, and a detailed design proposal in under 24 hours. We facilitate video conferencing to swiftly finalize your custom designs.

Custom Quartz, Exceptional Value

We excel in fully personalized quartz glass customization, leveraging extensive in-house capabilities: welding, hot bending, blowing, grinding, drilling, slotting, polishing, and coating. Our rigorous quality control and competitive pricing deliver exceptional value for your custom components.

Your Trusted Partner for Custom Quartz Solutions

Based in China's "Crystal Capital," Aoxin Quartz is a premier manufacturer of custom quartz glass components. Our 10,000 sq. meter facility houses advanced R&D, comprehensive processing capabilities (precision cold & clean thermal), and stringent quality assurance. We serve diverse high-tech industries with tailored quartz products and full after-sales support, making us your ideal one-stop partner for quality and innovation.